IKEA Store Energy Upgrade Project in Thessaloniki, Greece

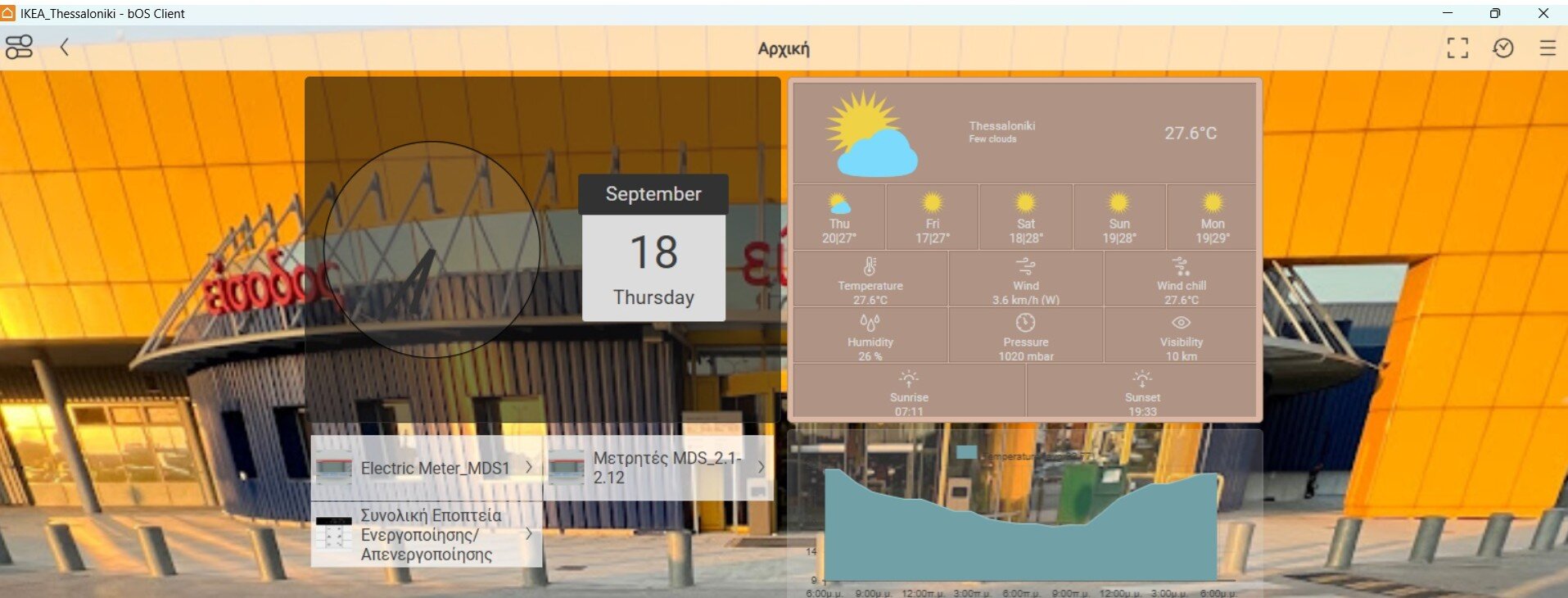

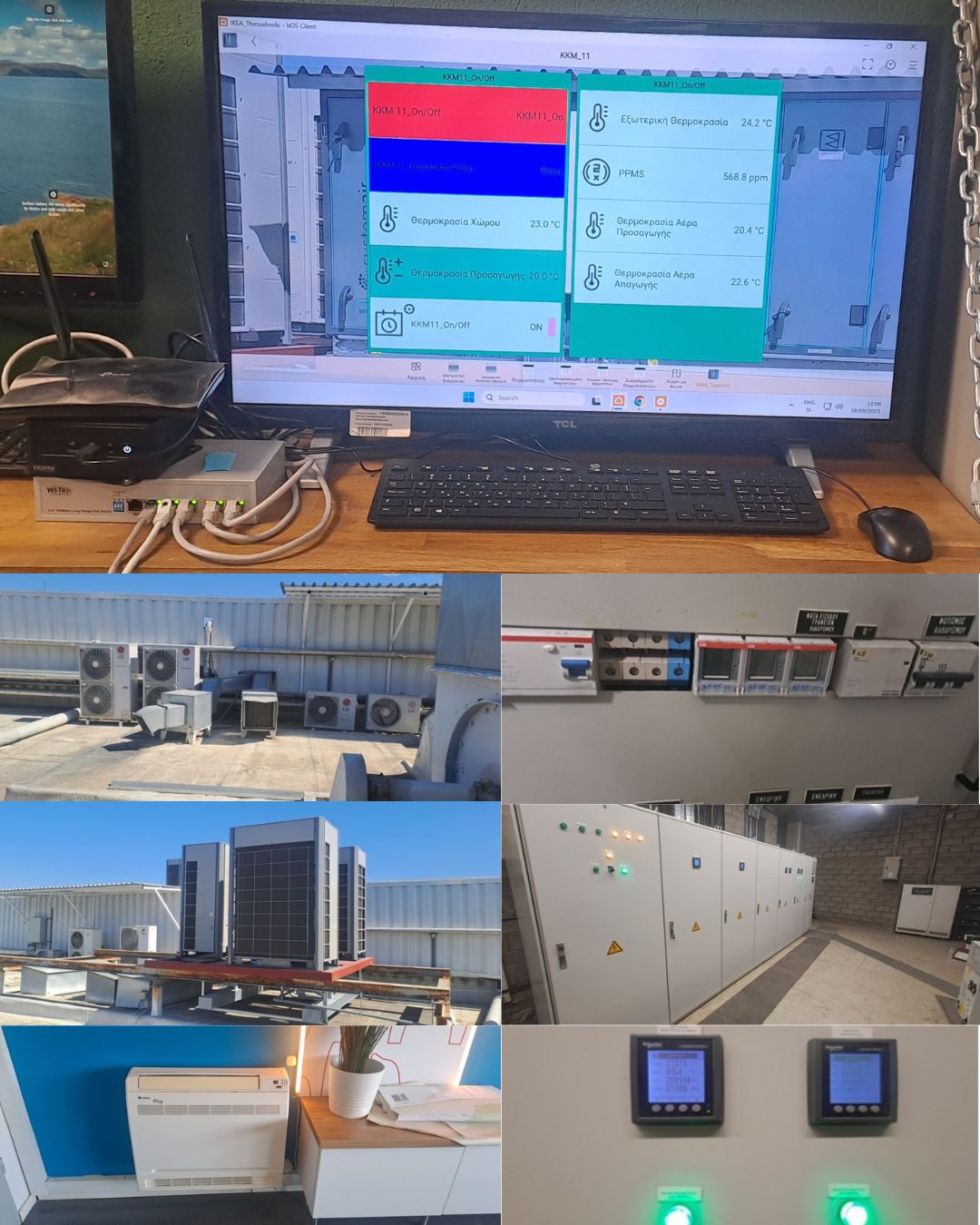

The IKEA Thessaloniki project focused on modernizing and optimizing the store’s air conditioning and safety systems as part of a complete energy upgrade. Using ComfortClick’s Grinder Black server, the system integrates multiple communication protocols to monitor, control, and visualize HVAC units, energy data, and safety alarms across the entire facility.

- Project Name: IKEA Store Energy Upgrade

- Project Location: Thessaloniki, Greece

- Year of Completion: 2025

- ComfortClick Products: Grinder

Technology Used

- KNX for thermostat control and IR transmitters for split air conditioners

- Modbus for three-phase energy meters and alarm data

- BACnet for Air Handling Units (AHUs)

- KNX digital inputs for alarm signal collection

- Intesis gateways for integrating LG, Mitsubishi, and Daikin fan coil units via KNX

Project Description

Developed by QSYSTEMS, this project aimed to improve energy efficiency, comfort, and operational safety at the IKEA store in Thessaloniki. ComfortClick’s Grinder Black server was chosen to unify all systems and communication protocols into one centralized platform.

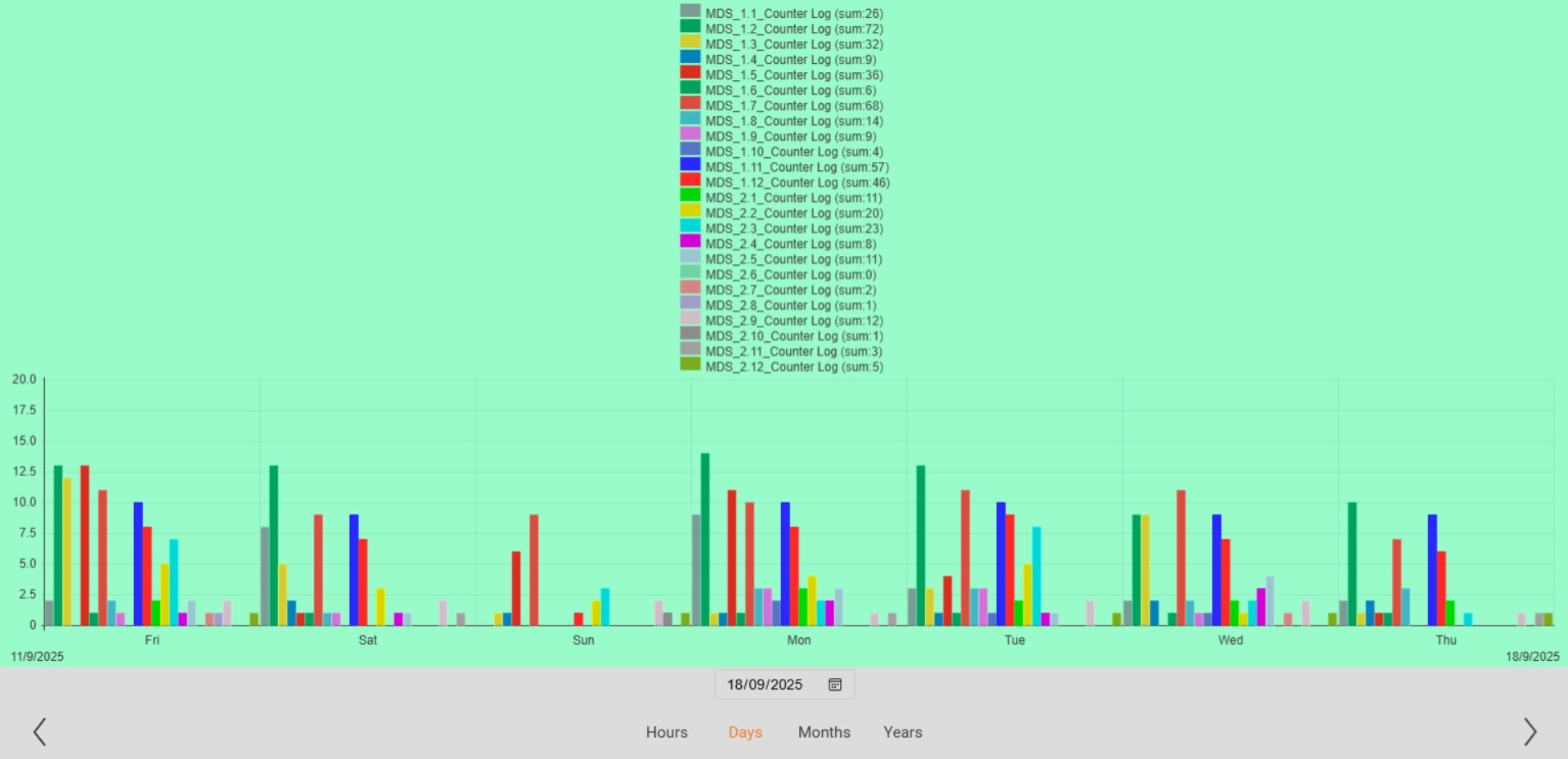

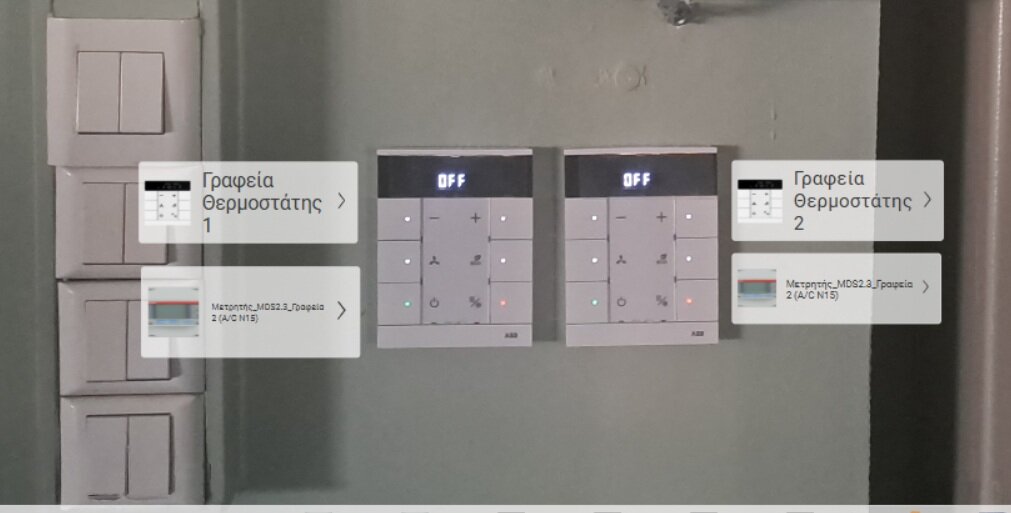

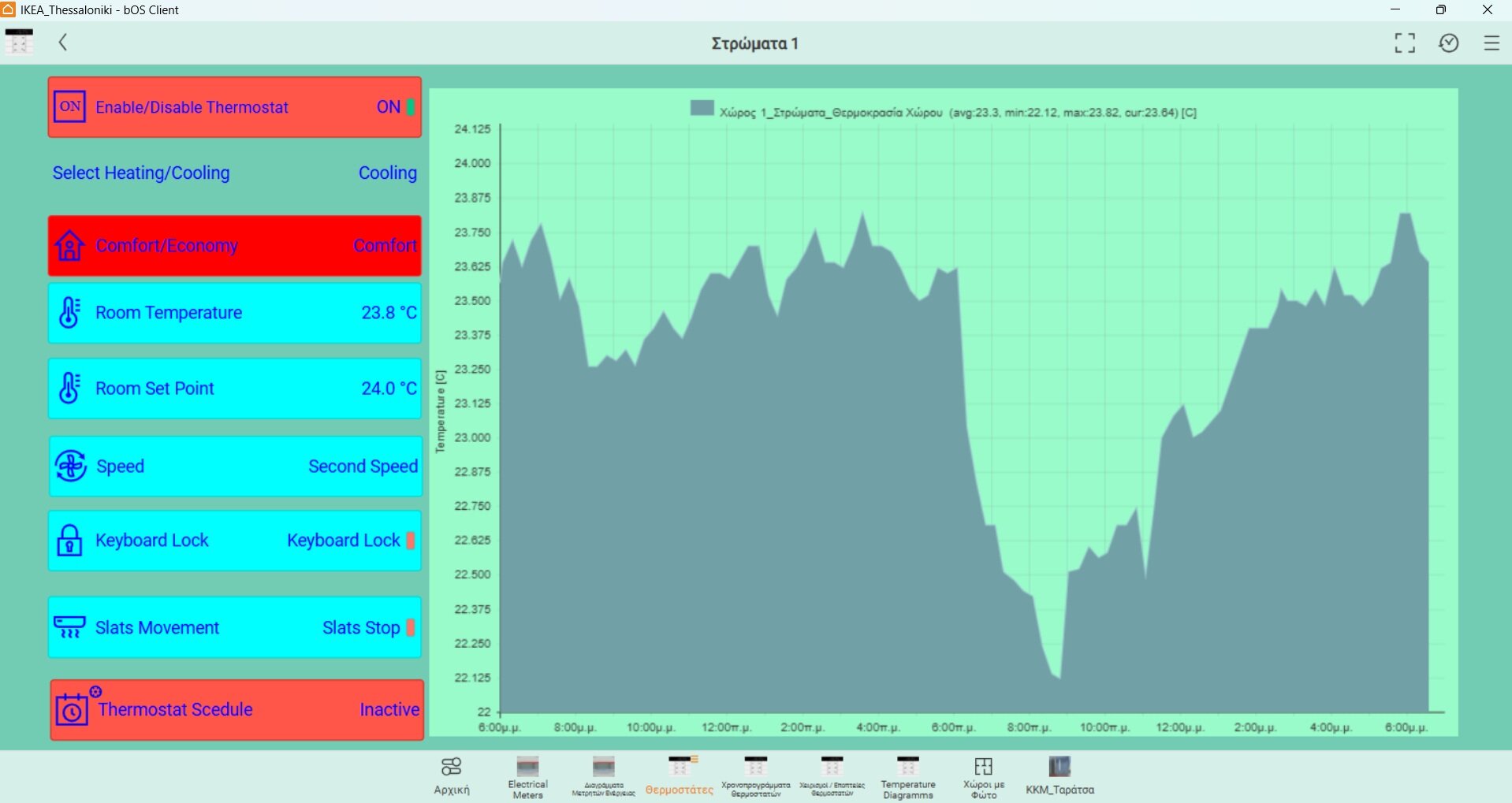

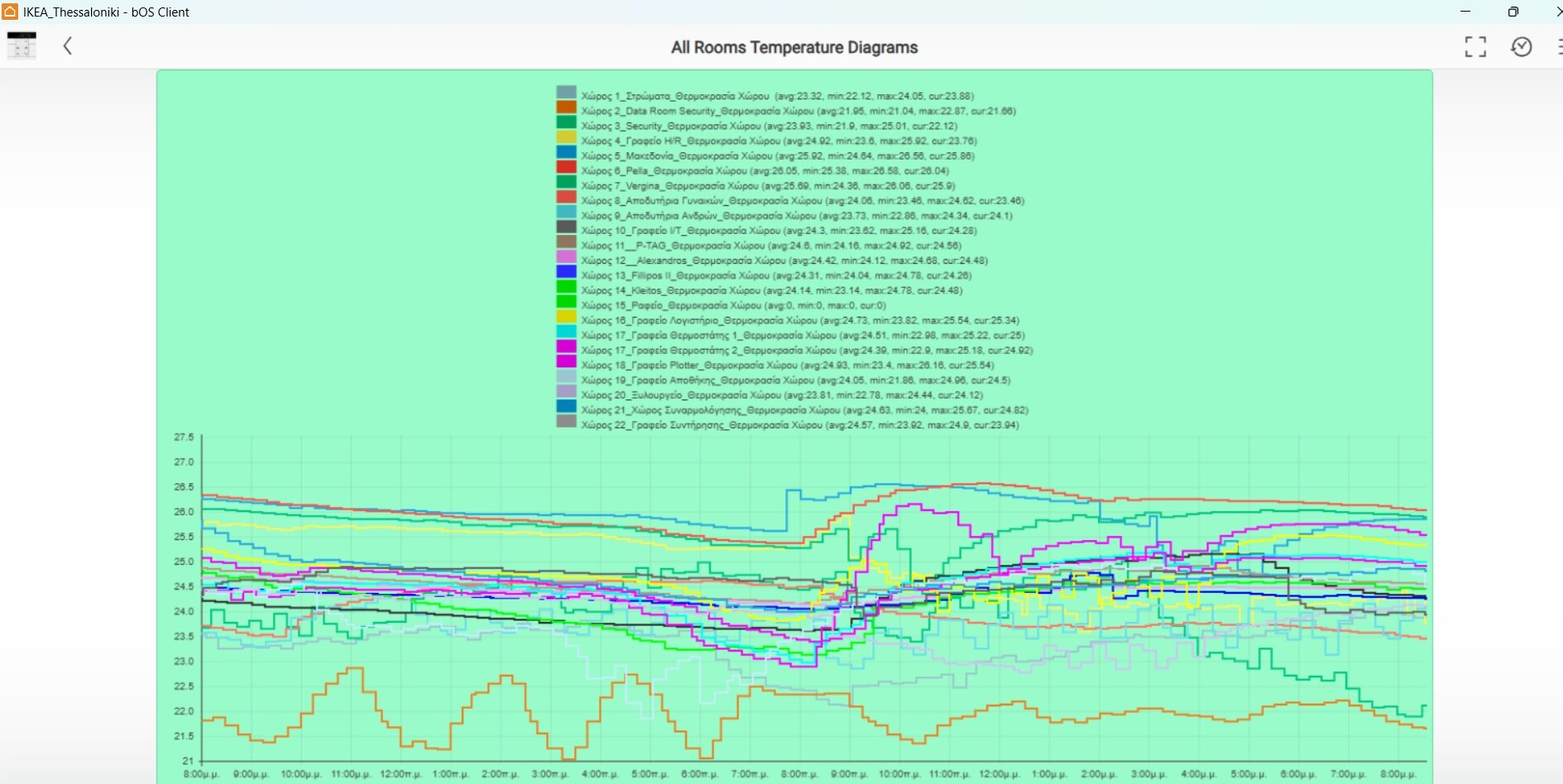

The BMS manages over 30 split air conditioning units, each controlled by KNX thermostats that simulate IR remotes. Through ComfortClick visualisation, technicians can monitor temperatures, adjust setpoints, switch modes, change fan speeds, lock thermostats, and control airflow direction. Each space also includes timers and data logging for room temperature tracking and energy analysis.

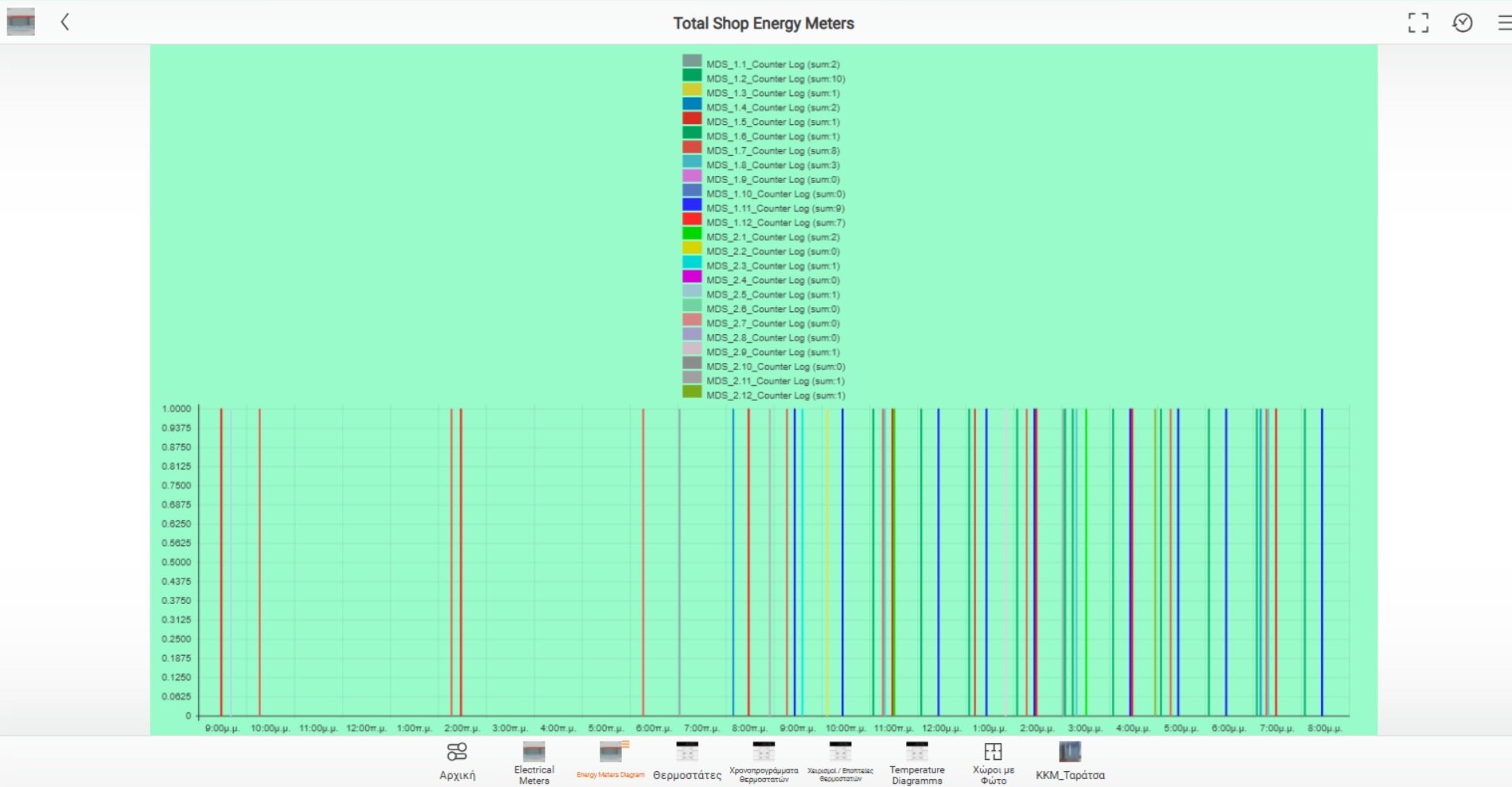

Energy consumption from each split unit is monitored by Modbus energy meters connected through KNX gateways. ComfortClick records voltage, current, and power values in real time, logging data into CSV or database files for analysis. Automatic alerts are generated in case of overvoltage or undervoltage, helping prevent equipment damage and energy waste.

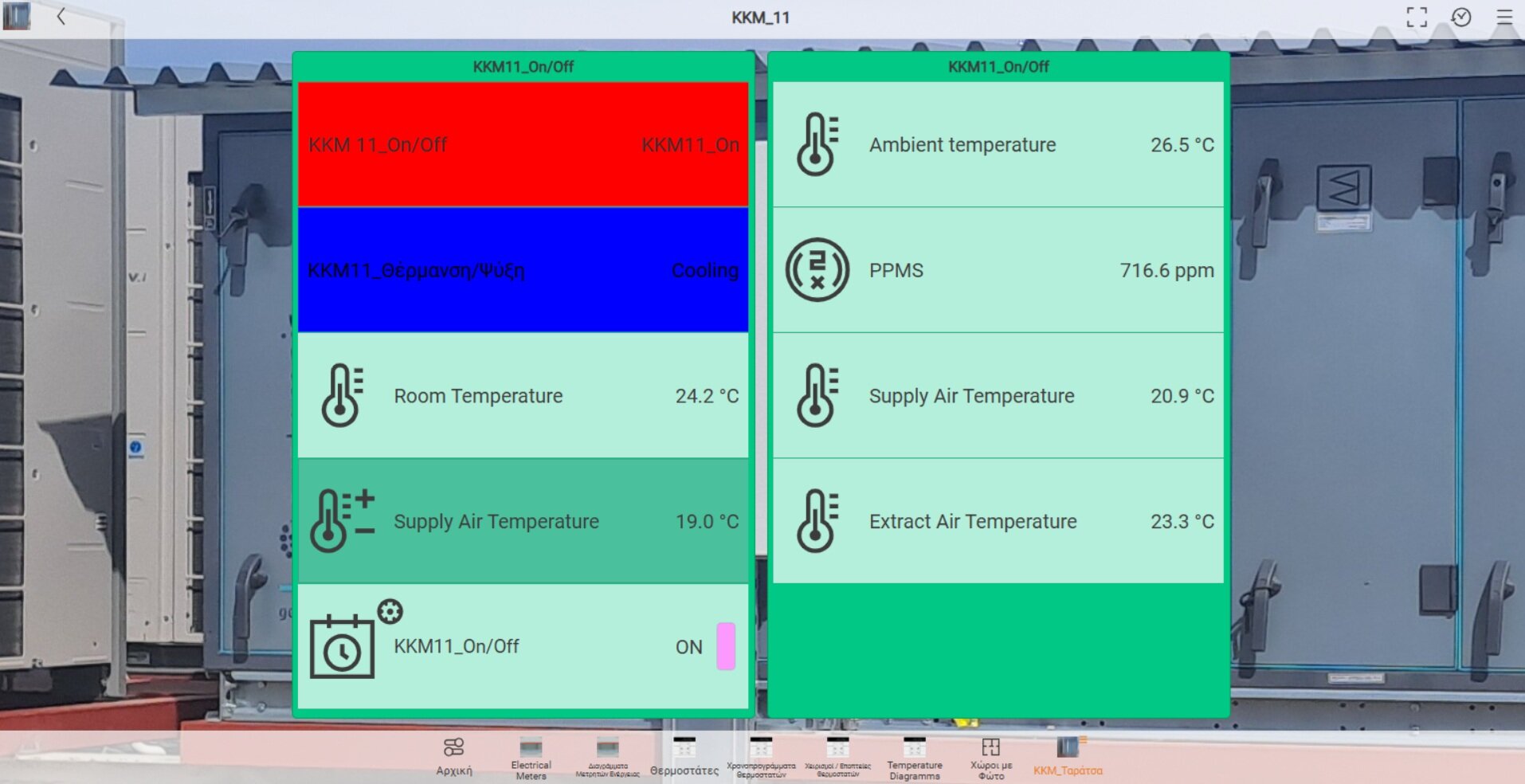

The system also manages 15 rooftop Air Handling Units (AHUs) with a combined 2,715 kW heating and 2,610 kW cooling capacity, communicating via BACnet for full control and visualization. Through ComfortClick’s visualisation, operators can view temperatures, air quality (CO₂ and ppm), filter status, valve positions, and motor temperatures, with automatic alarms for maintenance and fault detection.

Additionally, 26 VRV fan coil units located in checkout areas, technical departments, and customer spaces are integrated through Intesis gateways, providing full control of temperature, modes, and fan speeds.

The BMS also includes control and alarm monitoring for ventilation systems (VAMs), fire protection systems, and drinking water systems, ensuring safety and smooth daily operation. Through ComfortClick’s visualization, facility managers can easily monitor all equipment, receive alerts, and optimize building performance in real time.

By bringing together different brands, devices, and communication protocols under one platform, the system achieves significant energy savings, simplified management, and improved reliability, a major step toward a more sustainable and intelligent retail environment.

For more information about our partner, visit QSYSTEMS.

Servers

Servers Panels

Panels Licenses

Licenses Accessories

Accessories

bOS apps

bOS apps Examples library

Examples library Documentation

Documentation Video tutorials

Video tutorials Forum

Forum Knowledge base

Knowledge base Help desk

Help desk FAQ

FAQ