HVAC AHU REFRIG Project in Romania

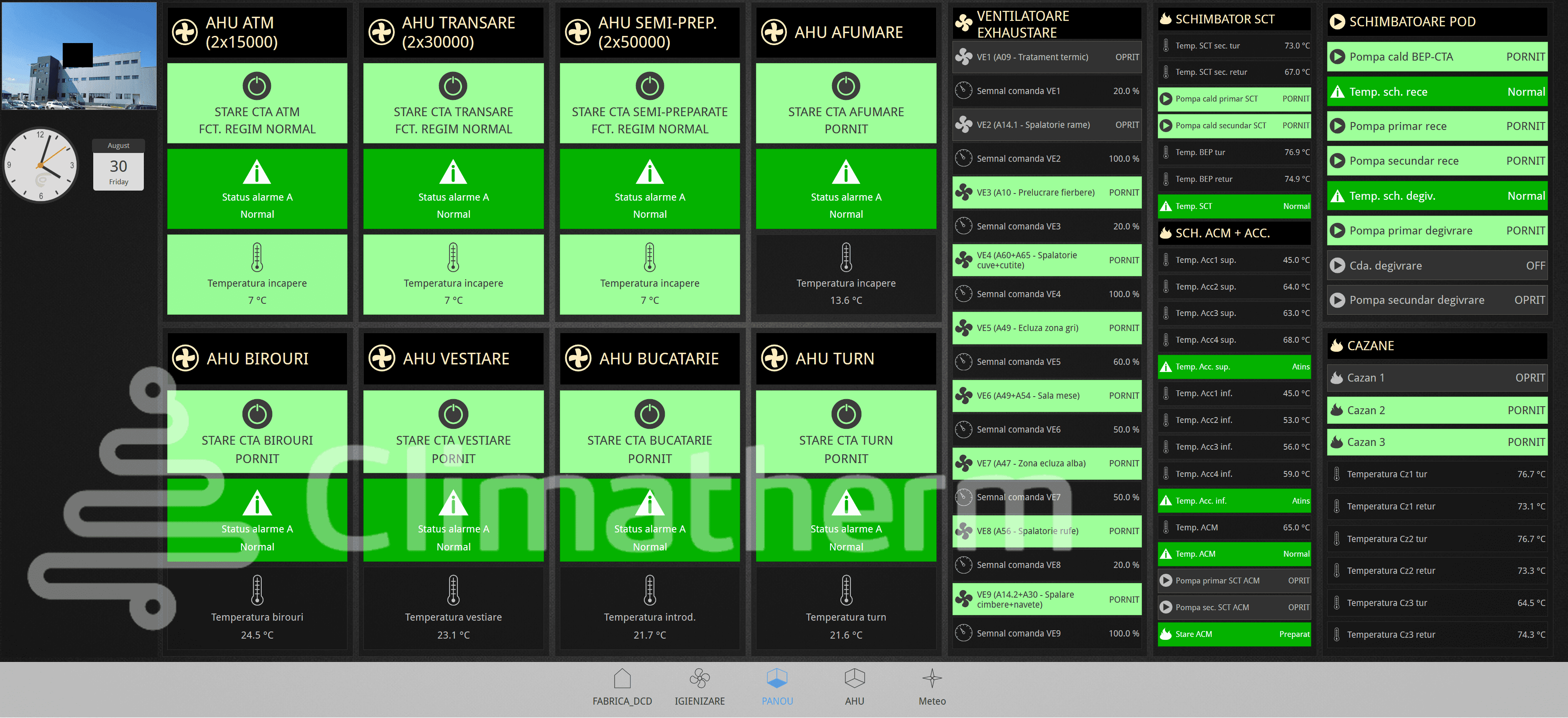

Our partner in Romania, CLIMA THERM CENTER SRL, led by Catalin Imbrea, has successfully completed the HVAC AHU REFRIG project, implementing an advanced industrial HVAC system. This project integrates ComfortClick's Jigsaw and Jigsaw Pro to manage all aspects of the facility's heating, cooling, and ventilation systems, ensuring seamless control and optimal energy efficiency across the entire installation.

- Project Name: HVAC AHU REFRIG

- Project Location: Romania

- Year of Completion: 2023

- ComfortClick Products: Jigsaw, Jigsaw Pro

Technology Used

- HVAC: For heating, ventilation, and air conditioning.

- Modbus: Integrated for ventilation control.

Project Description

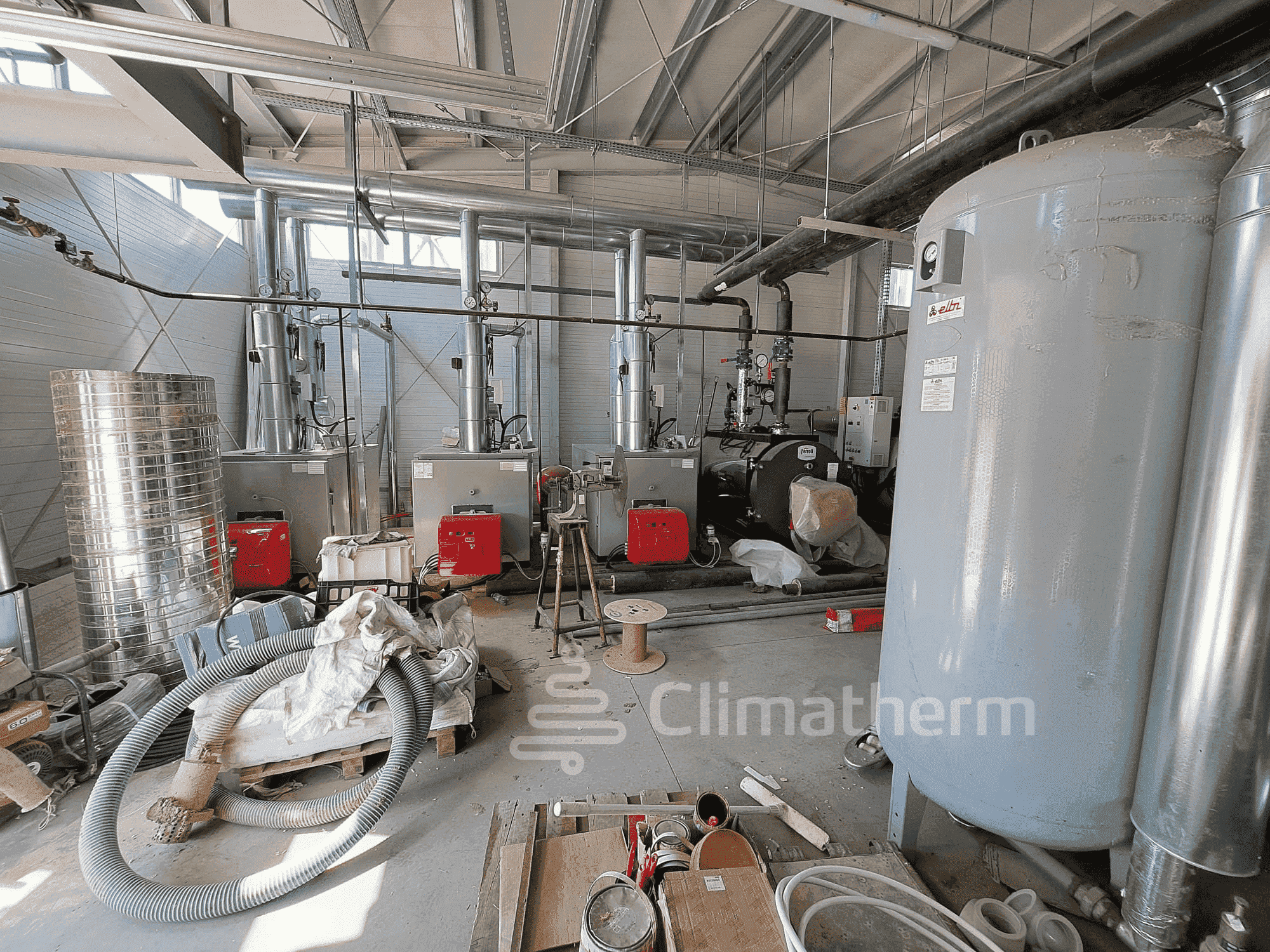

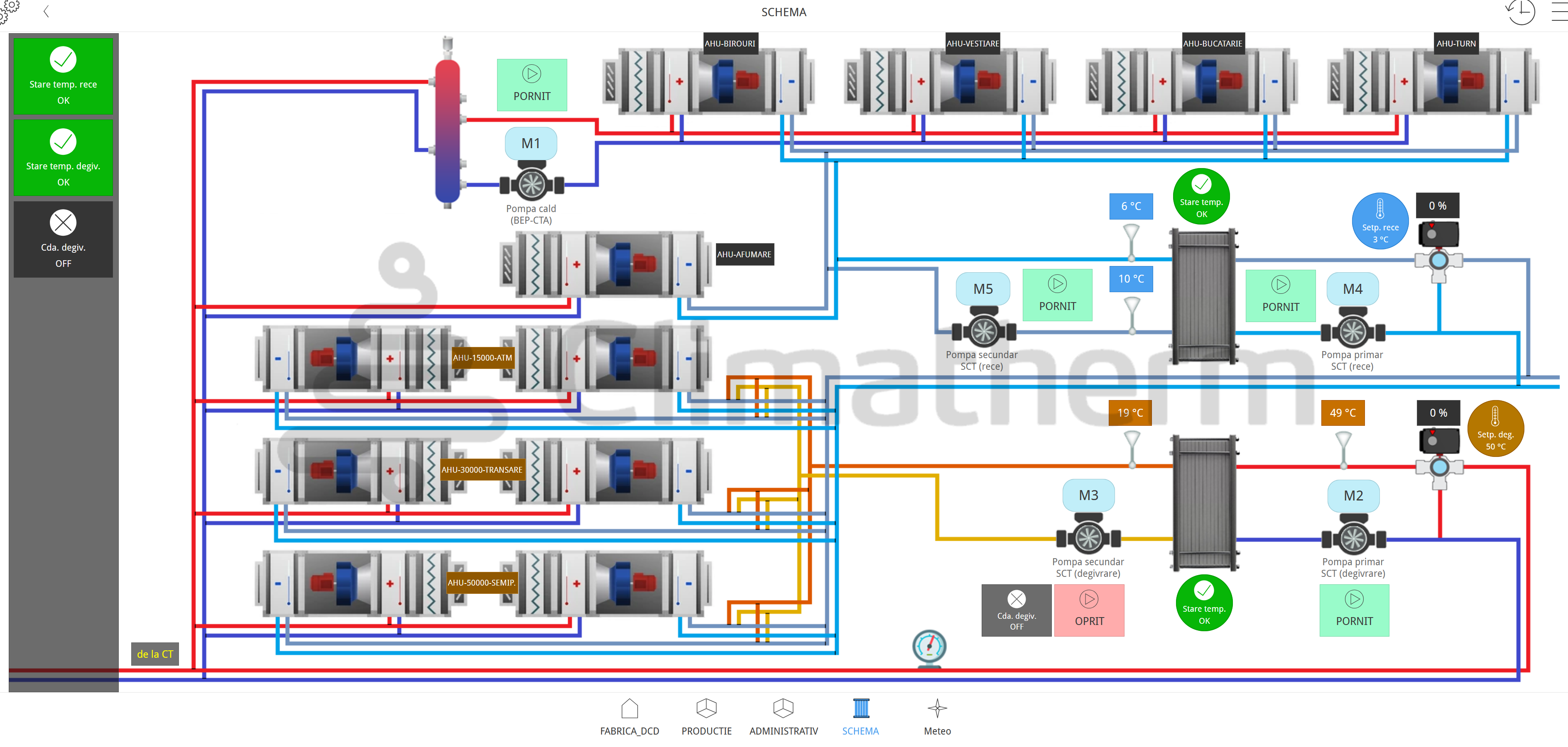

The HVAC AHU REFRIG project, completed in 2023 in Romania, is a comprehensive industrial-level HVAC system that services three key areas: the boiler area, production area, and administrative area.

The project was designed to address the diverse heating, cooling, and ventilation needs of an industrial facility while ensuring optimal system integration and energy efficiency.

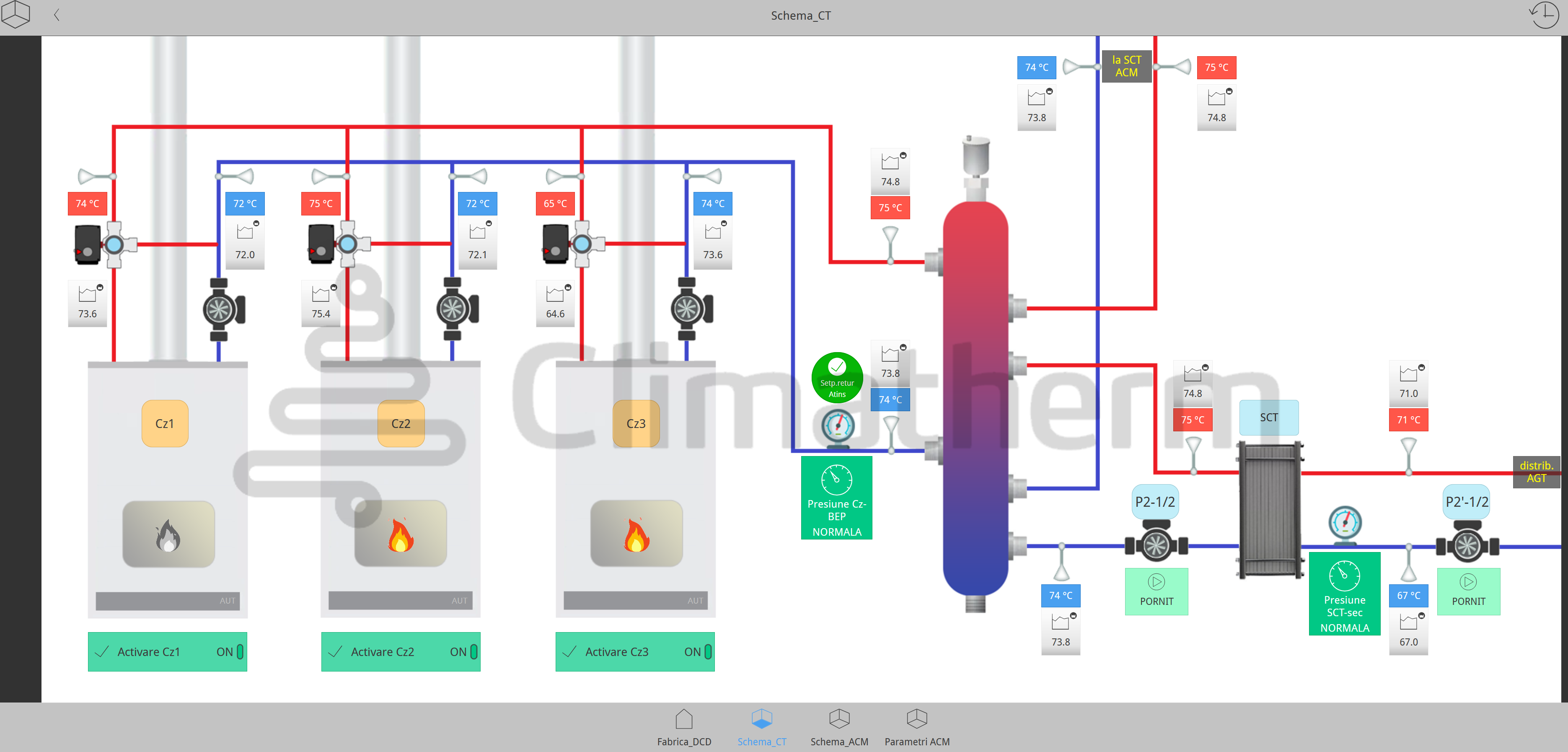

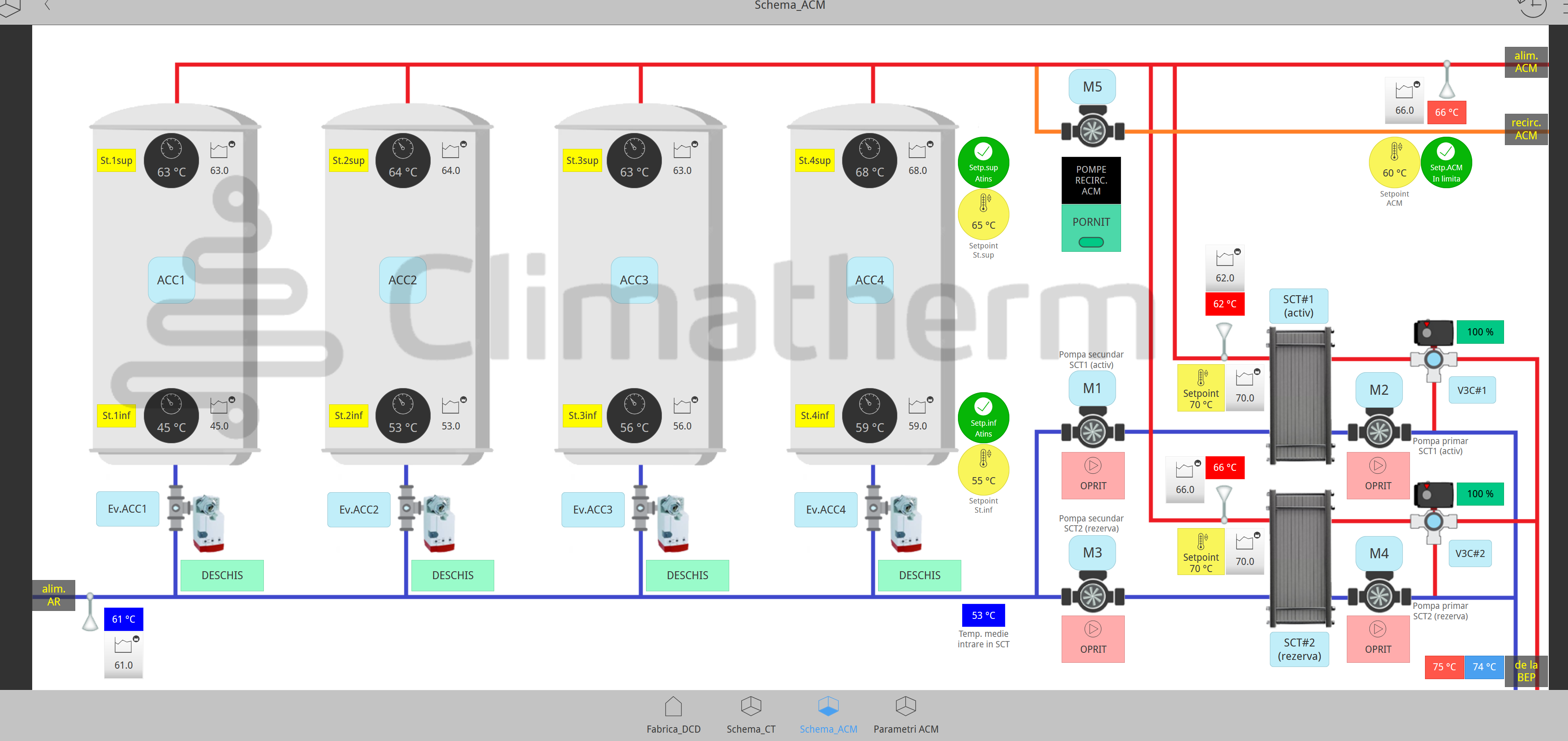

In the boiler area, centralized heating boilers were installed to support both the facility's heating system and hot water storage.

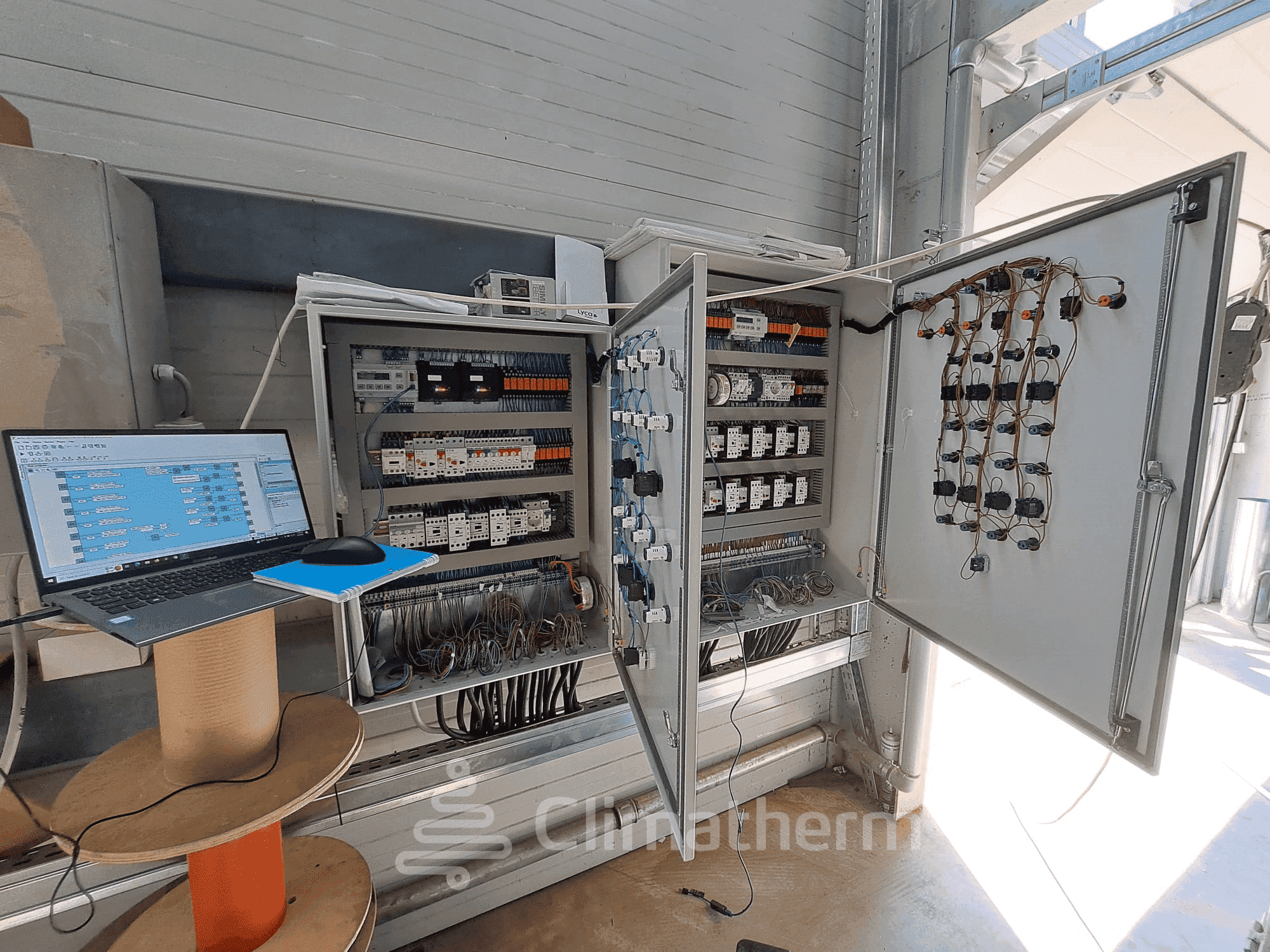

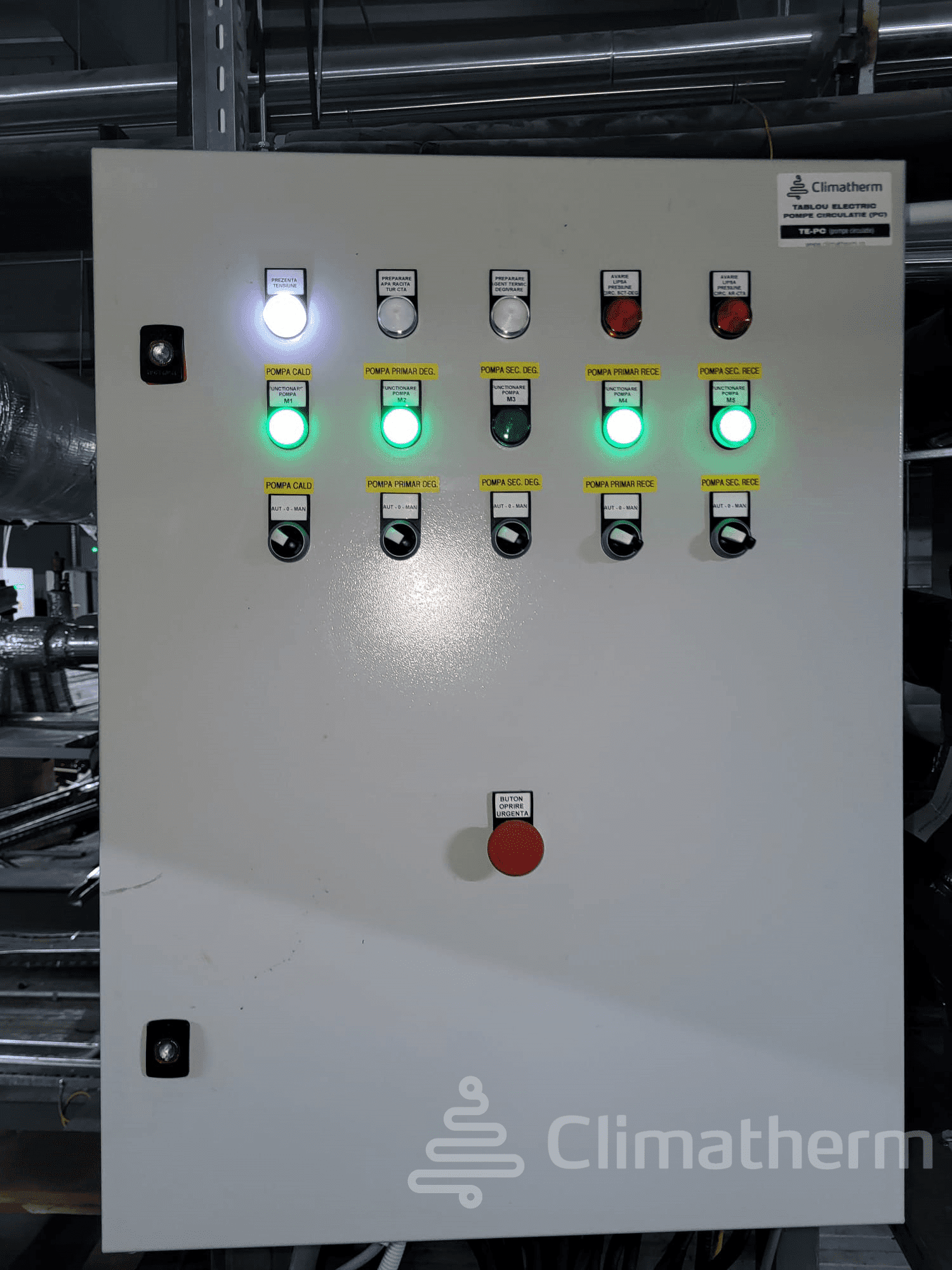

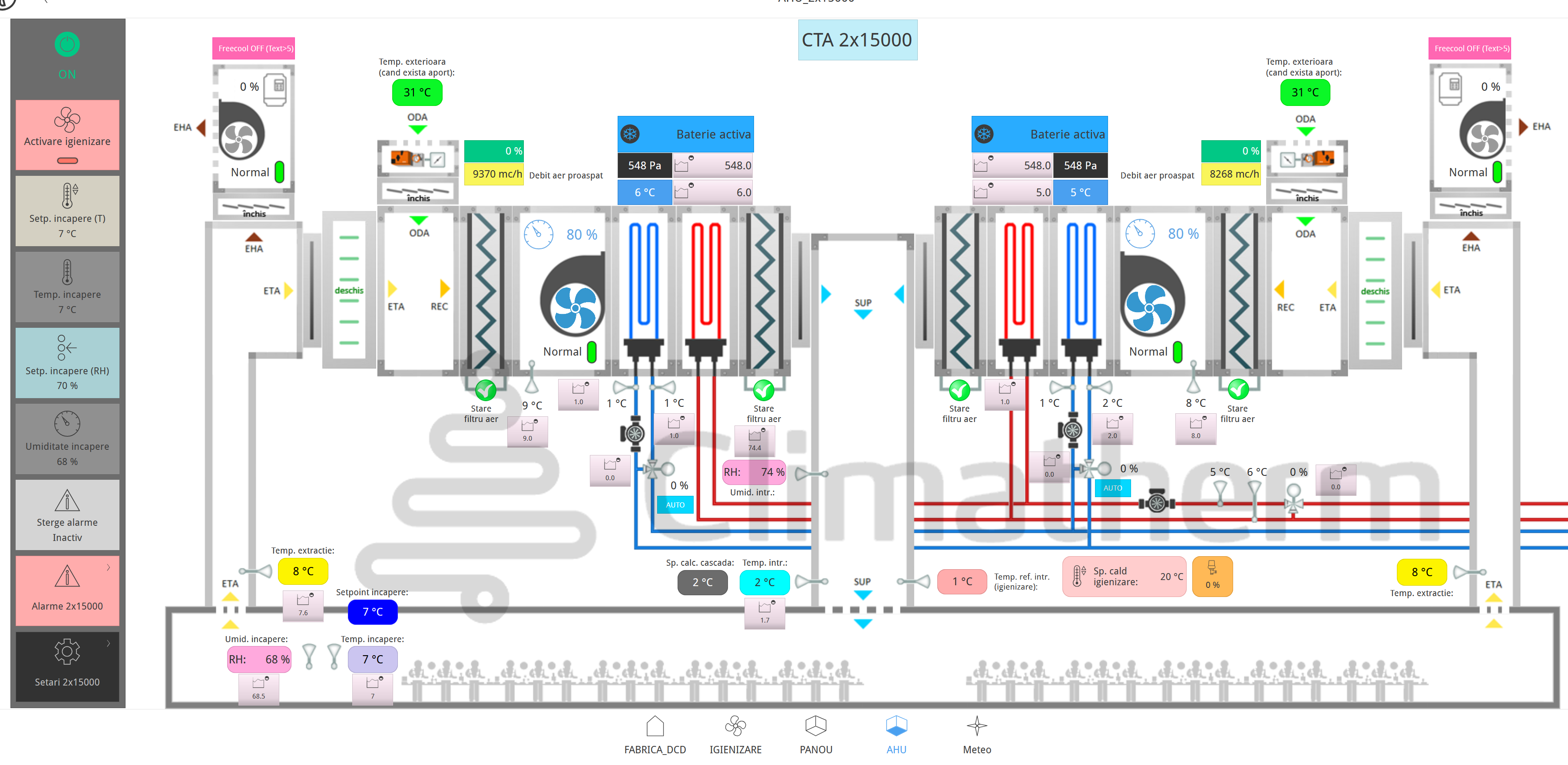

The production area was outfitted with Air Handling Units (AHUs) in a redundant 1+1 configuration, which maintains strict temperature control, ensuring the environment remains at 5-7°C, critical for the industrial processes.

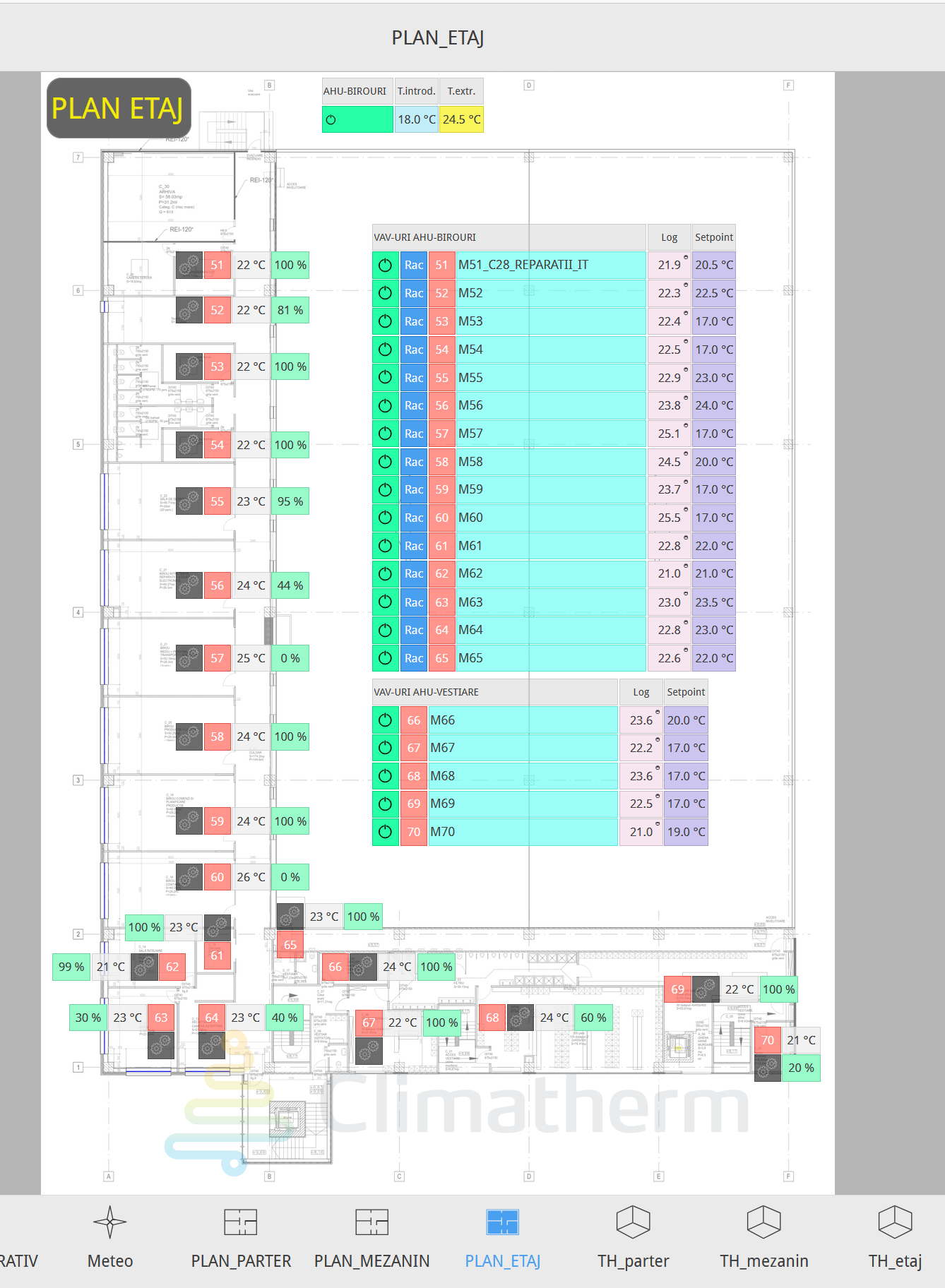

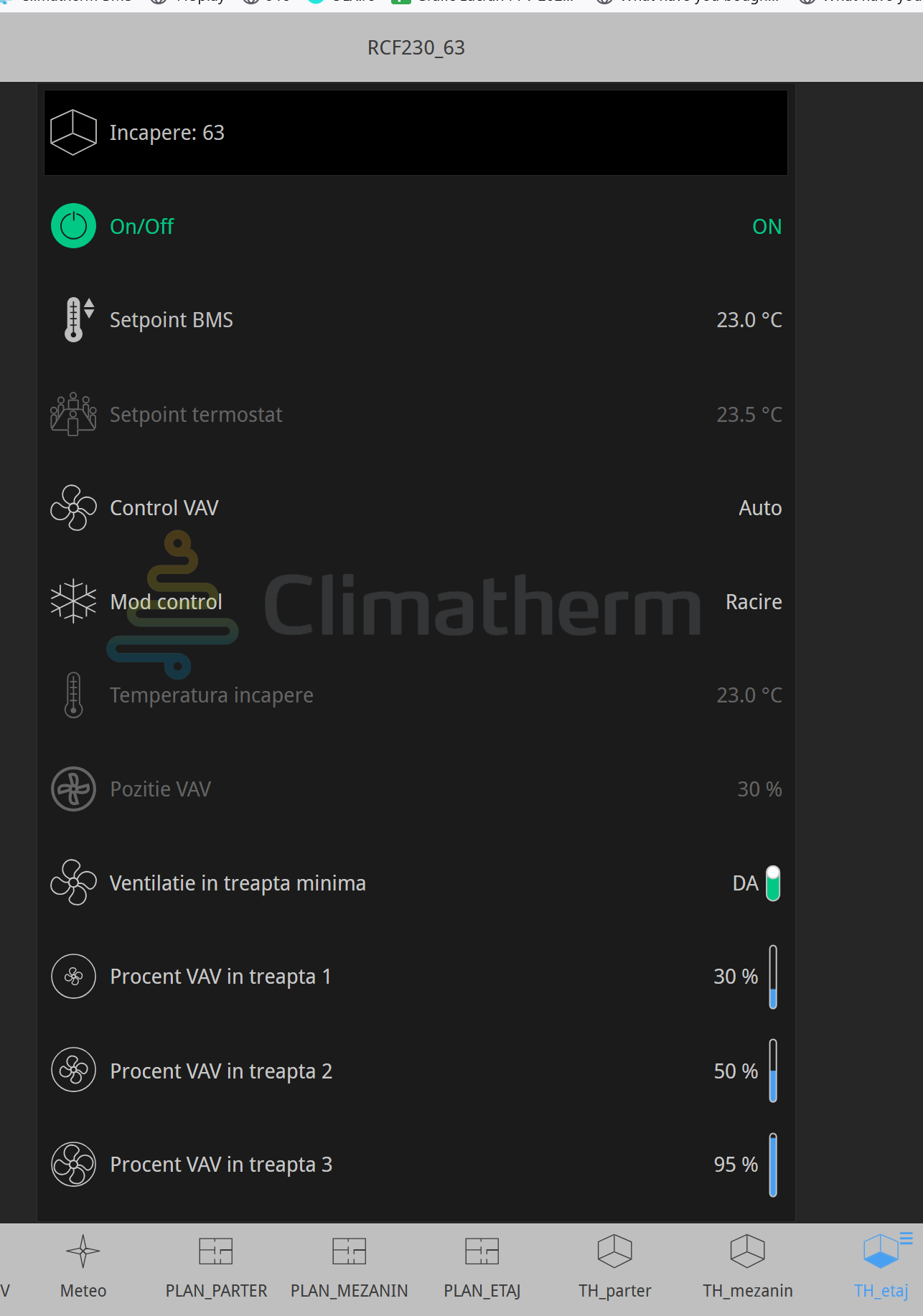

The administrative area combines AHUs with a Variable Air Volume (VAV) system and fresh air supply to maintain comfort and high air quality for staff.

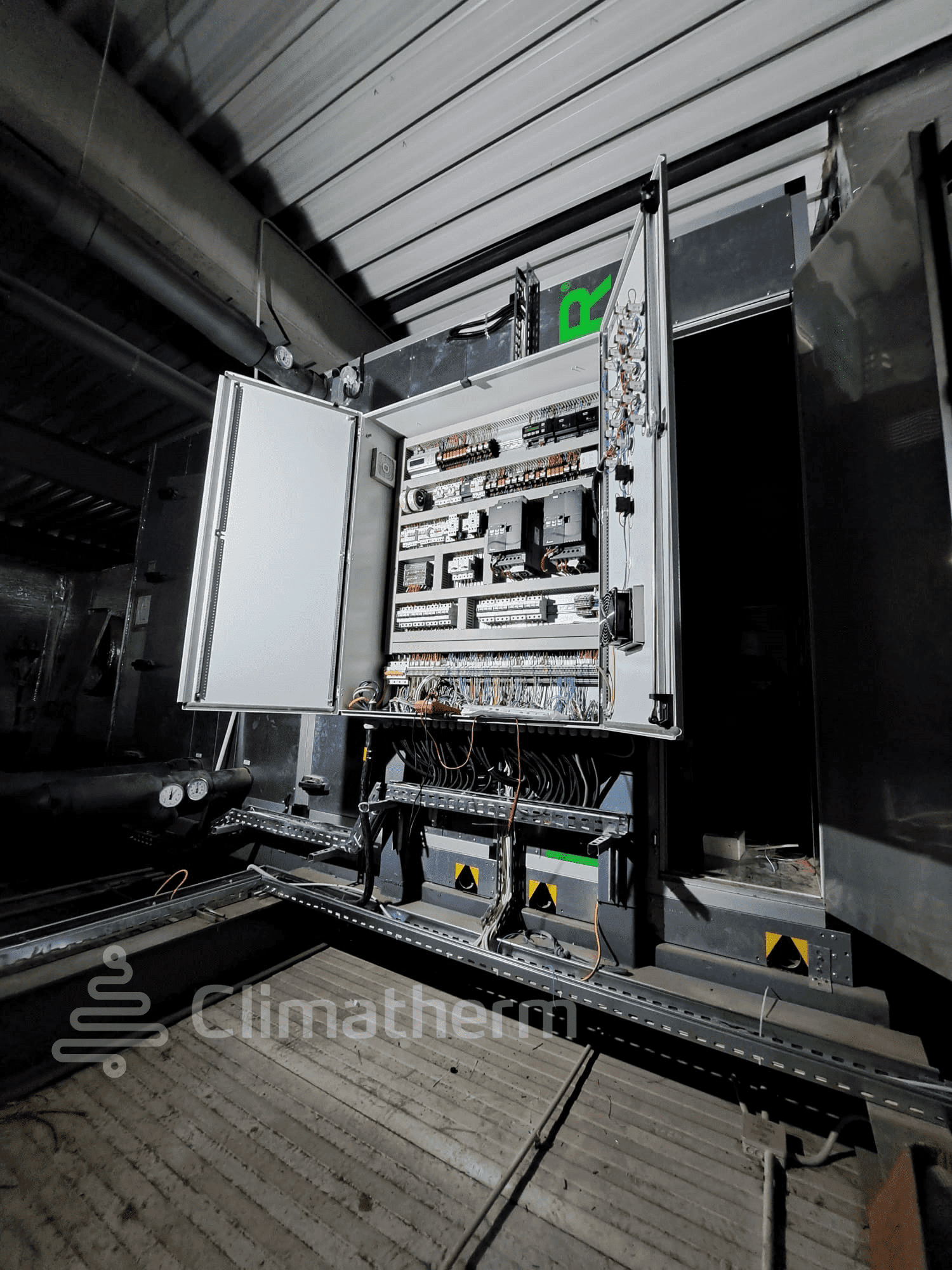

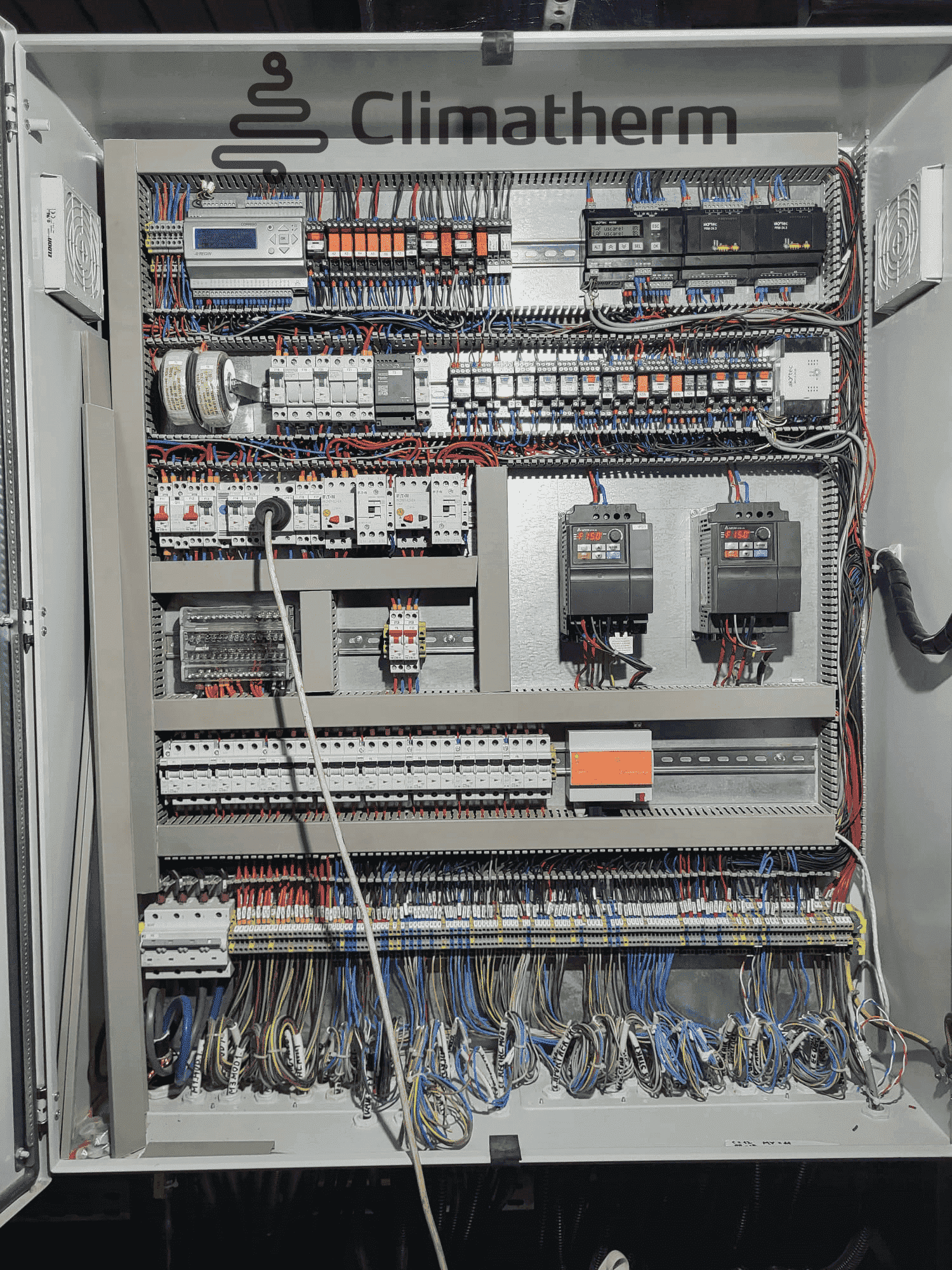

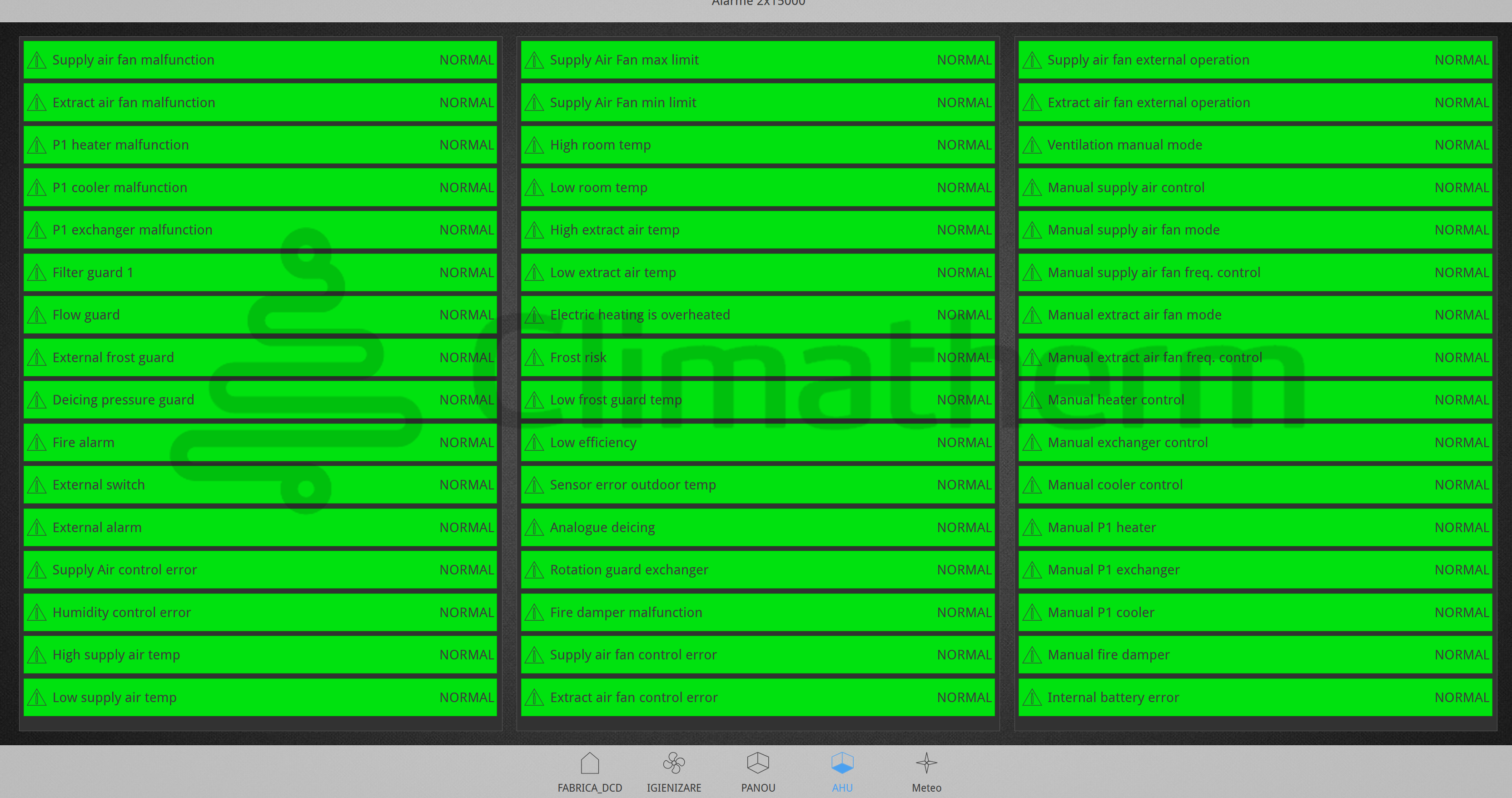

All major systems are integrated via Modbus, which connects the ventilation systems across four servers in a master-slave configuration, this setup allows centralized control of the entire HVAC system through ComfortClick's Jigsaw and Jigsaw Pro servers.

ComfortClick’s bOS platform provides a single, unified view of all equipment and systems, ensuring efficient monitoring and control of the facility.

This project is unique due to its scale and the complexity of its HVAC system integration.

With four integrated servers working together and the use of Modbus for streamlined ventilation control, this project demonstrates a high level of innovation in industrial HVAC management. The redundant AHUs add reliability, and the centralized control system enhances operational efficiency.

For more information about our partner, visit Climatherm.

Servers

Servers Panels

Panels Licenses

Licenses Accessories

Accessories

bOS apps

bOS apps Examples library

Examples library Documentation

Documentation Video tutorials

Video tutorials Forum

Forum Knowledge base

Knowledge base Help desk

Help desk FAQ

FAQ